Topic Categories

- Bottom Sampling

- Data Acquisition Systems, Data Management & Data Tools

- General Science Equipment and References

- Lab Equipment and Instrumentation

- Meteorological Data, Sensors and Systems

- MG&G

- Nets and Trawls

- Overboard Handling System - All Things Winches, Wires, etc

- Salinity and Salinometer

- Shipboard IT/Comms

- Shipping/Export Control

- Sonars and Acoustics

- Underway Seawater System

- Water Column Sampling and Instrumentation (CTD, sensors, etc)

- Video - All Things Video

Discussions

Box coring and bongo net deployment

August 27, 2010

Original Message from Rich Findley (U. Miami/RSMAS)

All,

Does anyone have written procedure for box coring and/or bongo net deployments.

Regards,

Rich

Replay From: Lynne Butler (URI)

Hi Rich,

Attached is a box core version I downloaded from the web years ago, "Courtesy of Rob Wheatcroft, OSU".

Also attached is a short cheat sheet for cores/pingers as well as a spread sheet for pinger crossings. Not specific for box vs. other cores. I hope they're helpful though. The spreadsheet could use some work. It's just something I threw together while coring and fill in during operations. Delete or edit if you don't like it and if you've got files you like please send them over.

Lynne

Box Coring Overboarding Procedures - Courtesy of Rob Wheatcroft, OSU => BoxCore.pdf

Pinger Box Core => PingerBoxCore.pdf

Pinger Box Core Log => PingerBoxCoreLog.xls

Reply From: Rob Hagg (UW)

Rich, is the procedure your interested in for the ISM or a howto for new techs that may not have done one before?

We wrote a " Deploying over the side" procedure that encompasses most over the side operations re all nets box cores, sediment traps etc. It basically outlines safety concerns an assumes the person in charge of the deck has been trained in the deployment of the specific instrument.

A step by step procedure on rigging and deployment of a box core for a tech that has never done one may depend on the type of box core. The Spade box core, Sutar box core an Castin box cores all rig a little different. Depth and bottom type may also play a part in your actual deployment procedure w,r,t. desent rate, or whether a pinger is needed etc. There are also a couple huge box cores out there requiring a little more caution an dollies to recover the box.

Bongo nets are much more straight forward but may have different safety concerns for the tech depending on the type of tow. Vertical or Horizontal...and I would imagine also somewhat ship dependent. For instance, a horizontal tow off the stern is a lot easier than over the side if its possible to do so.

Rob

**********************************************

Box Coring Overboarding Procedures

Courtesy of Rob Wheatcroft, OSU

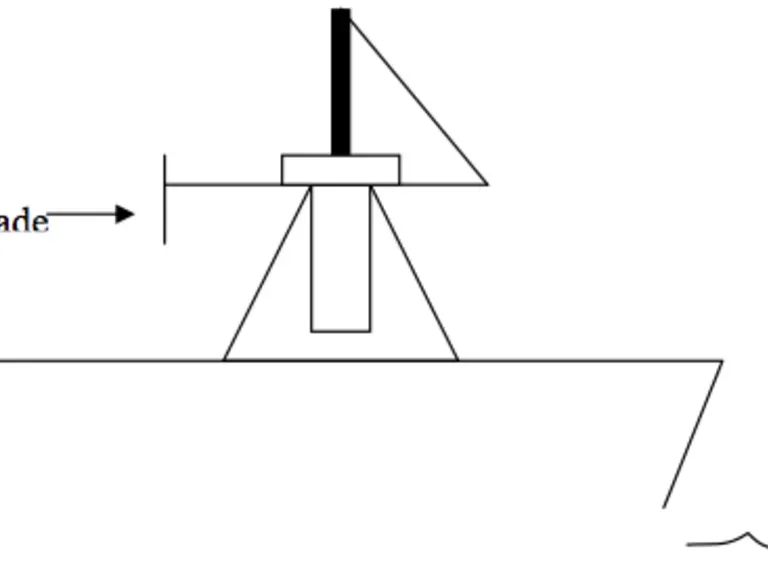

Box core is positioned under the A-frame with the spade portion of the arm forward and the thimble wire facing aft. The box is placed on the underside of the corer with the screwed-on face forward and secured with the long, stainless steel pins making sure that the clips are in place. This step sometimes requires a lot of jiggling and/or kicking of the box. Wood blocks are used to keep the doors above the box open for the descent.

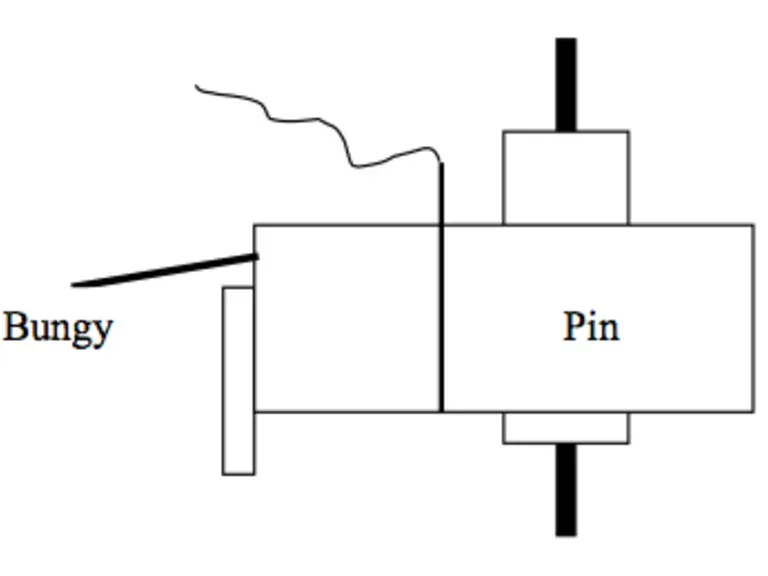

At the top of the corer the large, rectangular pin must be pushed through the thimble fitting (see below). That pin, which is attached to bungie cords, is secured in place by a small pin (a large cotter pin or nail works) with a 20-ft rope tied to it (this is the safety pin). In addition, the "goose-neck" bar is secured in the up position, thereby abutting the large pin.

Launch

Tag lines should be used in all but the most calm sea conditions, the corer is heavy and once it gets swinging it is hard to stop. Secure tag lines on the two legs. A third science personnel is needed to direct the operations and remove the two large (3/4 inch diameter) pins holding the column.

Take up slack and lift the corer 2-4 inches off the deck and stop. Pull the two large column pins. Put the corer over the side, keeping the safety pin in. Once the corer is in the water, slip the tag lines and then remove the safety pin by tugging on the line. Be careful that it does not come back and hit you in the face (it happens).

In the water

The corer is lowered at anywhere between 15 and 40 meter/minute depending on bottom type (sandy = faster). Upon contact with the bottom the winch operator must pay out an additional 2-3 meters, otherwise the box will not lower itself into the sediment. Pull out can be dramatic, so stand clear.

Recovery

Tag lines should be used on all recoveries. Have two hooks/lines with poles rigged and ready BEFORE the corer reaches the surface. Stop the corer when its bottom clears the sea surface. Attach the hooks to the leg supports and secure the tag lines to deck cleats. Bring the corer on board, but do not set it down before inserting the two large pins back through the column, try not to insert the flange on the pins past the gimbles. Maintain tension on the wire until the spade/arm can be secured, otherwise you run the risk of the spade going back to the horizontal position and you will lose the sample and possibly injure someone. Secure the arm/spade by flipping the shackle toward the column and sticking a big screwdriver through the shackle into the column. If you are uncomfortable with this setup then, improvise something else, but it is imperative that the arm/spade be secured before people start to take the box off.

Removing the box

First clear away most (but not all) of the sediment from around the bottom of the box, then insert a faceplate between the bottom of the box and the spade. Attach the faceplate with two clips. This step is not easy and requires much cajoling with screwdrivers, feet, etc. Once the two clips are secured, pull the arm/spade into the horizontal position. This step requires that the slack is provided to the wire by the winch operator. Once the arm/spade is horizontal use the handles to lift up on the box and pull the pins that hold the box in place. Set the box onto the deck and carefully move it to a secure position where it can be processed. Try not to slide the box on the deck as you risk knocking the faceplate off.

Repeat several 100 times... Contact Chuck (nittroue@ocean.washington.edu) with any questions. Good luck!!

**********************************************

Deploying the Box Core with a Pinger

Before Deployment: Open/Print PingerBoxCoreLog.xls Note water depth from the Echosounder because it will not give a bottom depth after "PingerMode" is on Tell the deck boss, winch operator & bridge the value of the bottom depth

On Deck: Deploy BoxCore, remember to pull pins!!! Down to 75m Turn on Pinger using screwdriver in switch Attach pinger using lanyard & 2 book clamps Use long screwdriver to tighten eye nuts on book clamps Gradually down at 40-60m/min

In Main Lab, on Knudsen Echosounder: Note the approximate depth of the pinger (from winch meters wire out) when PingerMode is turned onto keep track of crossings.

Toggle HF Channel to Off Setup, PingerMode 1 sec Processing gain up to 2 to 5 Log meter wire out at each crossing (it might be different than package depth if there's a large wire angle)

If bottom = 3020m, crossings would be 750m apart at:

500m 1250m 2000m 2750m 3500m

Speed of sound ~1500m/sec. Round trip ~750m/sec, sound goes to object & back.

On Echosounder display, 1000ms = 750m, 100ms = 75m

Bottom- 750m * (# of crossing from bottom) = crossing depth 3500m- 750m*1=2750m 3500m- 750m*2=2000m...

Tell the winch operator 100 meters above the bottom.

"Doghouse, Lab, BoxCore is 100m above bottom"

When core appears to touch bottom:

"Doghouse, Lab, BoxCore is on the bottom" (or just yell "HIT" depending on where you are in relation to winch operator)

Winch operator - let out more wire for 3-10 sec Winch operator - stop the winch Winch operator - start bringing in wire at 10m/min

At max tension peak:

"Doghouse, Lab, BoxCore is out of the bottom" Winch operator should increase speed to 60m/min until 100mwo A few minutes after core is back up off bottom, take screen shots of winch tension plot, pinger trace and 3.5KHz echosounder.

On Deck: At 75mwo, Remove pinger book clamps, then lanyard Turn off pinger Recover BoxCore

**********************************************

Box Core with Pinger Log

link to uploaded document here

Back to Top of Page

**********************************************

Serial Port Replicators (2014)

Originated by Alex Ren/LUMCON 19 Feb 14

I'm looking for recommendations for setting up serial port hubs in the labs on the Pelican. We're curious if anyone's recently found something off the shelf or if anyone has any instructions to build our own.Our goal is to have at least 3 per lab, so 6 total.I should clarify, I've looked through previous discussions and saw a couple about UDP and serial over ethernet. We've tried this and while it's great when it works, we've found it to be fickle from one scientist's computer to the next so we'd rather stick with supplying physical db-9 serial ports to the scientists' computers.

Thanks,

Alex

Reply from: Dale Chayes/LDEO 19 Feb 14

The COTS solution that I have used extensively are from Black Box. They are simple, big, relatively expensive, and very robust.

http://www.blackbox.com/Store/Detail.aspx/RS-232-Data-Sharer-8-Port/TL554A%C4%82R3

SIO has an in-house implementation that is physically smaller that they might be willing to provide.

-Dale

Reply from Bill Fanning/URI 19 Feb 14

Alex,

We have had great luck with Black Box TL159A

http://www.blackbox.com/Store/Detail.aspx/Data-Broadcast-Unit-RJ-11/TL159A

We have 10 of them in use full time, several have been running for 20 years. With 8 output ports, no setup required and rock solid they are a great investment at $312.

Bill

Reply from Kurt Schwehr 19 Feb 14

Why not serial over TCP? Â socat has the built in capability to fan out to N clients. Â You can even do filtering and other fun stuff. Â e.g. Â get something from port 31414, only get data from a particular sensor, and expose that on port 35001.

socat -u TCP:localhost:31414 - | grep 'r003669945' |Â socat -d -d -d -v -u -TCP4-LISTEN:35001,fork,reuseaddr

-kurt

Reply from Alex Ren 19 Feb 14

Yes, we've tried that as well but with mixed results. It works just fine for some guest scientists' computers but it doesn't work for others. We'd really like to find something that can provide us with extra DB-9 serial ports.

Alex

Reply from Tom Wilson/Stonybrook 19 Feb 14

Hi Alex,

What exactly are you trying to accomplish?

One RS232 transmit to many?  I.e. broadcast NMEA0183 GPS or timeclock to all laptops? Many RS232 concentrating to one?  i.e. four instruments or systems all with RS232 outputs going to one RS232 input? Command driven multiplexing?  One master computer converses with any of a number of slave computers?  If so buffered or unbuffered? Same baud rate or different? I've done all of these things through the years both with straight RS232 and serial over IP.  Black Box and B&B Electronics used to offer a lot of these solutions but some of the older ones are likely discontinued but maybe available on eBay.  There's always Arduino and Raspberry Pi and hacking (oh my) which can do almost anything (if you have the time & talent to do it or the money to pay a guru like me).Let us know some more details and maybe I can give you some COTS solutions.

Tom

Reply from Alex Ren/ LUMCON 19 Feb 14

Thomas,

Yes, we'd like to take 1 RS232 to many. GPS, Gyro heading, motion reference unit, etc.

William,

Those look interesting! Are those RJ45 ports? While I'd prefer DB-9, I think we might be able to make something like that work.

Alex

Reply from Tom Wilson/Stonybrook 19Feb14

AHA and never mind my questions because I just remembered these:

http://www.bb-elec.com/Products/Serial-Connectivity/Serial-Data-Tools-Adapters/Serial-Data-Switches.aspx

Very flexible and reliable, does any of the things in my previous message right out of the box. Â I retired the last of these a few years ago after 10+ years of use, glad to see B&B still makes them.

Tom

Reply from Tom Wilson/Stonybrook 19Feb14

Alex,

On further consideration, the B&B box is outstanding when trying to concentrate serial data down to one port but Fanning's recommendation is what you need to go the other way.

Best,

Tom

Reply from Bill Fanning/URI 19Feb14

Alex,

They make a DB-25 version as well but it costs more. The box doesn't transmit control signals so the 4-wire RJ-11 connector is all you need. Buy yourself the RJ crimp tool with the money you save - you will never go back to the DB connectors again.

Bill

Reply from Robbie Laird/WHOI 19Feb14

I'll probably regret admitting this.....You don't really need a buffer. It's surprising just how much stuffyou can pile onto a single serial feed before the voltage drops to thepoint where something stops working. Obviously this has to be doneith some care, but in reality, we have been doing it this way foryears, and never felt the need to change. It Just Works.Of course, maybe you put your critical items on a separate feed. Buteven then, you can still have 2-3 items on the same line.The RJxx system works well. We use RJ12 connectors, (6 wire, buteveryone calls them rj11), somewhere in the past there is probably an ISA serial board that used 6 wire connectors. We use these

http://search.l-com.com/search?keywords=ra096 from L-com (or search l-com for ra096) We also use these: http://www.l-com.com/patch-panel-server-rack-350-32-port-panel-rj12-6x6… Again, we just wire a bunch in paralell and it works. With the 16 port version, (not sure they still make it though), you can have, say, 5 gps, 5 gyro, 3 posmv, 3 whatever....Kramer makes 4 way buffer/splitter thingy, the VP14. http://www.kramerelectronics.com/products/model.asp?pid=194 Note,this one has a unique ability to cause trouble because it does exactly what it says it does. "It sends data from any port to the other three." So DON'T give the user access to the TX line, because if the send any data, it comes out the other ports. (and tries to talk to your gps, the other users, etc..)

Other buffer/splitters.

General Electric makes one, but I cannot find the part number. http://www.overland.no/device.html makes some. I'm not familiar with these, but they look nice.

http://www.marinelektronik.se/lemming.htm has some as well. I'm not sure how easy these are to locate. while the above items are mostly 422, they also have 232. The UDP over ethernet has some very cool features, but it's true that going directly into the users computers does not work very well, mostly because the software is not set up for it. (opencpn is set upfor it, and it works great.) But you could use a four port Moxas http://www.moxa.com/product/NPort_5410.htm to provide serial at the user. They are not cheap, but neither are the other solutions. With one moxa "upstairs" to broadcast the data, any moxa anywhere else on the network can pick up the data. There is also a cool trick you can do, which is to broadcast more that one data string one a single udp port. Because TCP is magic, they will not step on each other. And when you read the same UDP port, you get all the data on one port. (and one serial port, if you want) So it can multiplex the data. One drawback is that you cannot guarantee the order. With some thought, the moxa's are very powerful. You can also do baud rate conversions.

Robbie Laird

WHOI/SSSG

Reply from Toby Martin/OSU 19Feb14

From: rlaird@whoi.edu

Date: Wed, 19 Feb 2014 17:10:22 -0500

I'll probably regret admitting this.....

> Yeap :-)

You don't really need a buffer. It's surprising just how much stuff you can pile onto a single serial feed before the voltage drops to the point where something stops working. Obviously this has to be done with some care, but in reality, we have been doing it this way for years, and never felt the need to change. It Just Works.

> Until it doesn't. Then you have a REALLY FUN time attempting to figure out why the system that has been working fine is now FUBAR.

Toby

Rely from Dale Chayes/LDEO 19Feb14

From: rlaird@whoi.edu

Date: Wed, 19 Feb 2014 17:10:22 -0500

I'll probably regret admitting this.....

> Yeap :-)

But it does serve to stimulate the discussion. We can all use it as a learning opportunity. Thank you

You don't really need a buffer. It's surprising just how much stuff you can pile onto a single serial feed before the voltage drops to the point where something stops working. Obviously this has to be done with some care, but in reality, we have been doing it this way for years, and never felt the need to change. It Just Works.

> Until it doesn't.

Such as when someone inadvertently connects a power source or an electrostatic discharge to an improperly protected serial line and kills all the devices.Have a look at: http://www.analog.com/static/imported-files/tech_articles/571756556RS-2… You can be sure that there are manufacturers of serial port devices that don't provide appropriate protection.Then you have a REALLY FUN time attempting to figure out why the system that has been working fine is now FUBAR.

Been there, done that. It's a lot easier when there are only two devices in the movie.

-Dale

Reply from Webb Pinner 19Feb14

We used these on the Okeanos without issue. Pretty much just like what Bill recommended but maybe a little more suited for the marine environment. http://www.actisense.com/products/nmea-0183/nbf2.html

Cheers, Webb

Back to Top of Page

**********************************************